- The U.S. semiconductor industry is booming, fueled by significant investments under the 2022 CHIPS and Science Act. Yet, sustainability challenges loom large.

- Automated intelligent water management tools offer a solution, helping fabricators meet sustainability goals while maintaining profitability and operational efficiency.

In The Post

The U.S. semiconductor manufacturing industry will bounce back with a $280 billion boost from the 2022 CHIPS and Science Act. The construction of new plants is set to receive $39 billion while $11 billion is retained for research, making Arizona, Pennsylvania, and Texas microchip production centers. This surge in growth trajectory anticipates an industry worth that reaches at least one trillion dollars by the close of this decade. Nonetheless, as demand increases, so does the environmental impact, especially through water and energy use. It should be noted that over 3000 gallons of water are used to make just one smartphone, which calls for innovation.

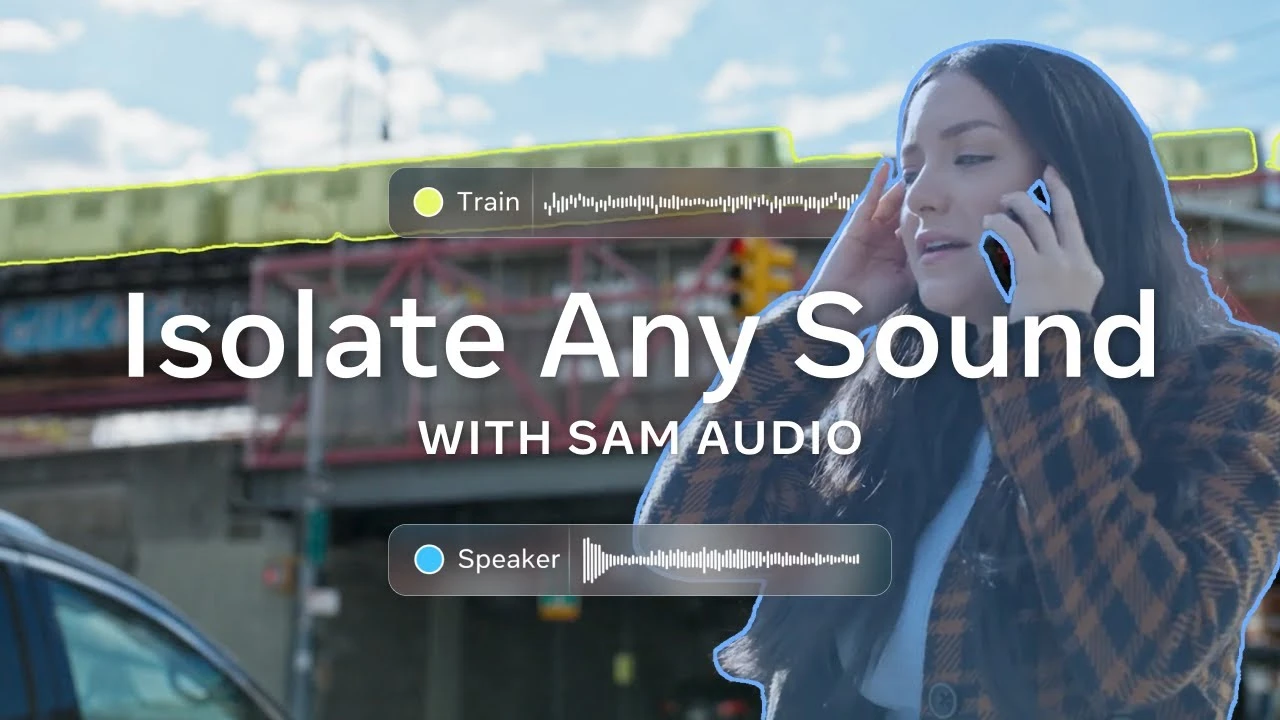

Automated smart water management has been a game changer in semiconductor fabrication. Such systems utilize digitally enabled tools of inspection and measurement to optimize water usage without compromising product quality. To exemplify this case study, we can take Nalco Water, which is an Ecolab company. Through a partnership with NXP Semiconductor and the application of 3D Trasar technology, Nalco has saved several million gallons of water as well as reduced its wastewater discharge significantly. Being able to monitor treatment processes by way of sensors and IoT integration in real time calls for efficiency plus sustainability.

Read More: Unlocking Industrial Potential: Cisco and Rockwell’s APAC Partnership

Indeed smart water management carries additional benefits beyond saving H20s. For example, millions of gallons were saved by a manufacturer of data storage equipment through using 3D Trasar technology; there was also a reduction in energy consumption and CO2 emissions, thus creating substantial cost savings. Proactive control over water quality flow rates and possible operational problems is made possible through this integrated system comprising smart sensors, touch screen controllers, cloud, and information systems, resulting in sustainable, optimized manufacturing operations aligned towards achieving environmental goals and improving profitability.

In conclusion:

Water management automation is changing the face of the semiconductor sector with a view to future sustainability. Manufacturers can achieve much lower environmental footprints and still enhance their operational efficiencies and overall profit margins if they adopt these smart technologies. Inculcating such advances within the industry will be vital in pursuit of sustainability as the industry expands.

Latest stories :

CrowdStrike Update Sparks Unprecedented Global IT Chaos

Meta clarifies AI content: “Made by AI” evolves to “AI Info”

OpenAI’s Bold Step: Developing In-House AI Chips